[2022-01-09: corrected some factual errors (in red) - thank you @ajy_krish and @shellvedge!]

|

| ACME (or Acme) shoemaker skin-stitched special Oxford. Made-to-order 2021. |

There is no dearth of Acme shoemaker reviews from the bloggers and KOLs - with some of them having multiple pairs made already:

ShoeGazing.com (Jesper Ingevaldsson)

The Shoe Snob (Justin FitzPatrick)

@ThunderMarch (Winston)

@shellvedge (David)

Here, @shirtingfantasy is going to review his own process of MTO from Acme (or ACME?) in 2021, and provide some initial feedbacks on fit and construction.

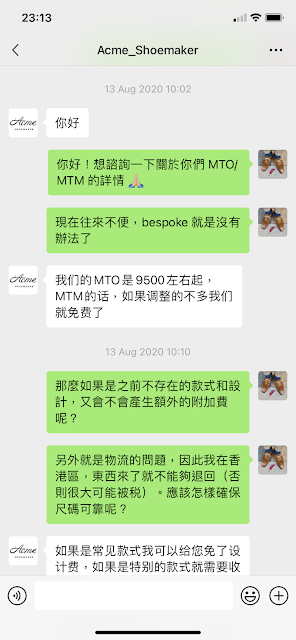

A bit of flashback - when the COVID-19 was still pre-Delta/Omicron, and when Acme was first launched:

Back in August 2020, Acme MTO was RMB 9500 (USD 1490). As of late 2021, the official price for MTO is quoted as EUR 1250 / USD 1450. From what is understood, VIP customers of Medallion Shoes (the mastermind behind Acme) would receive preferential rates. @shirtingfantasy did not have enough purchases with Medallion to unlock that.

Almost a year later, after MTOs and Special Orders with some other makers, @shirtingfantasy suddenly had the impulse to order a pair of seamless back double monk (a.k.a. JL Chapel-mimic) from Acme because of the deterioration of finishing and leather quality of JL Prestige in recent years (so the lesson is, seeing bad shoes from one brand can lead to purchase from another, better brand).

Initial communication was through the chat function on Medallion Taobao store, which was quickly switched to WeChat (effectively our National messaging platform for the Mainland region):

Tim from Medallion very smoothly coordinated for me my contemplated Chapel-clone, and quickly liaised with workshop head Mr Oliver Tang to pick for me a nice piece of Zonta museum calf.

@shirtingfantasy is not a shoe enthusiast, or someone with particular shoe-luck in general: in China, it is difficult to source the exact type of metal buckle used by JL. Local shoe enthusiast @fishball_boy_in_hk suggested that the buckles could be purchased from Poursin Paris, yet after weeks of communication Acme has not been able to convince Poursin to ship to Mainland China - which, as some readers may know, has rather stringent import laws and tax policies than some sellers would rather not deal with. @shirtingfantasy's passion for a Chapel-clone also waxed and waned. At that particular juncture, the Frenchness of another design caught the eyes of @shirtingfantasy:

|

| MY NEW LIFE AT BERLUTI : AN INTERVIEW WITH ANTHONY DELOS (https://www.parisiangentleman.com) |

How about a Delos-clone? With extra handwork? That's how it happened. The order sheet prepared by Tim is self-explanatory.

As the payment to Acme / Medallion involved a bank transfer with currency exchange (HKSAR China uses HKD, while Mainland China uses RMB) and non-negligible fees, @shirtingfantasy asked Tim if it would be possible to have the added cost of the long skin-stitching seams absorbed into the added leather cost of the Chapel-clone (it was above 10% on top of normal MTO cost). Tim quickly liaised with Mr Tang, and we all agreed that it would be a fair arrangement for everyone. So, final cost of the pair: USD 1880 or around EUR 1660 (Acme asked for a small surcharge for receiving money in USD instead of RMB).

After some back-and-forth, we settled on their so-called almond toe last (F75) - which to @shirtingfantasy is just another smart round last (the prototype dumb-round last would be Edward Green 202).

This experience also highlighted a few things about shoemaking in Mainland China:

1. While sourcing is partly solved by Acme's initial investment of some EUR 800,000 80,000 into European and American (mainly Horween cordovan) leathers, the "trimmings" such as sole leather, metal parts, linings etc. are still some of the unsolved variables in the quality equation. Whether their magnitude is large enough to affect the wear experience is an open question.

2. Due the unavailability of Google in Mainland China, some easily available sources of information maybe unavailable to Medallion and the workshop. For example, the quality difference between Horween Russian calf and Baker Russian calf is not well-known, even in the enthusiast circle or among the sales associates. Due to the sourcing difficulties as described in (1), there could also be incentive to persuade the customer to choose what they already have.

3. Making itself is very fast - even for fully handmade shoes - see the unboxing part.

Some obligatory in-the-making shots:

The final shoes arrived on 26 December 2021 - the perfect unboxing on a Boxing Day!

|

| The tweed bags are actually very nice |

After a few hours of polishing (@shirtingfantasy is not a shoe expert, again), the shoes were ready for some garden shots:

While many budding enthusiasts are into "photo scams" (照騙), the seasoned enthusiast always look at post-wearing performance:

|

| After two full days of wear. The slight excess at the vamp created the bunging of leather. Creasing is otherwise quite fine. |

So, what's the final verdict?

The Goods

1. Work looks neat. If you are not into the endless debate as to how to blind a waist, whether the wheel marks are done by machine or by hand, whether the waist stitching is real or fake (it has been discussed among some domestic and overseas shoe experts) and just want to wear some nice-looking shoes, Acme is the right maker. They deliver a package that can elevate your mood.

2. Work is fast. Despite the initial delay and actual start of making in early November 2021, shoes were received on Boxing Day 2021, which is unthinkable if you attempted to commission a custom pair from European (their artisanal perfection uses celestial, flexible time scales) or Japanese makers (they simply have an inflexible wait list).

3. They are willing to clone, to innovate, or even to create. Another virtue of Chinese is pragmatism, they tell you what they can do, what they would need extra money to do, and what are impossible to do given their constraints. Cloning does not hurt their pride - Chinese is not particularly prideful compared to some Continental makers. Whether making near-exact clones of shoe styles is ethically right has been repeatedly discussed by The Shoe Snob and Shoegazing.com and needs not be repeated here.

The Bads

1. Sourcing is an issue. Certain options such as Baker leather sole, peccary leather, special buckles are difficult to coordinate if not outright impossible. Many exotic pairs in sharkskin and crocodile have been made and shipped domestically, but export status is uncertain and elephant or hippo seem outright impossible.

2. Acme restricted the finishing fineness of their MTO range. Outsole stitching is fixed at 9 10 SPI and only bespoke clients can choose higher SPI options. Seamless shoes also attract a significant surcharge.

3. MTO and MTM do not allow the modification of toe shape. According to Tim, special toe shapes would require bespoke. Also, the client's bespoke last can only be used for subsequent bespoke orders (unlike, for example, a client's bespoke last may be used for lower-tier orders). This is also unlike

The Caveats You Can Avoid

1. Wrong sizes can be avoided by meaningful communications with your sales associate. Tim of Medallion maintains a last comparison library and his shoe size is just 0.5 UK smaller than @shirtingfantasy - conversion and extrapolation therefore is easy and meaningful. If you have not ever worn any proper leather shoes ("I know my Nike size, it's US 9")), or live consistently at the extremes of the sizing scale (e.g. 4.5 Corthay or UK 13 John Lobb Paris), then going straight to MTO could be very dangerous.

2. Reasonable expectation is the key to happiness. @shirtingfantasy's pair has a small blemish on the inner side of the waist of one shoe, presumably due to edge paint staining the upper. @shirtingfantasy eventually decided to fix it himself. Some argue that USD 100 / 1000 / 10000 shoes should be PERFECT. It is hard to comment on moral dimension of expectations, but it would be healthy to self-adjust such that your reasonable expectation is one that doesn't fail too often.

|

| Is it a small blemish? Should it hurt you? |

SUMMARY

Acme (or ACME) shoemaker is an emerging maker from China which offers customised, fully-handmade shoes (hand-lasted, handwelted, hand-sewn outsole with a fast turnaround time. The cost is comparable to certain smaller European makers (e.g. Antonio Meccariello, Maftei), and significantly lower than fully-handmade ranges from some established makers (e.g. Yohei Fukuda MTO with bespoke craftsmanship upgrade at around HKD 30000, Gaziano & Girling Optimum at around GBP 2750, Corthay Petite Mesure at around EUR 4000). Upper design is flexible, but finishing options are limited by price-tier. Due to sourcing issues, certain "trimmings" may not be easily available. Sizing can be advised by Acme's team of sales associates. The author considers his Acme one of his more enjoyable pairs of dress shoes in terms of overall ordering, receipt of the actual product, and initial wearing experience.

ACME Shoemaker

Minimum order: 1 pair

Price range:

RTW - from around RMB 8600 (Medallion webstore)

MTO/MTM - from around RMB 9500

Bespoke - from around RMB 15000

Handmade options: "hand-lasted, handwelted, and hand-sewn outsole" for all ranges

Comments

Post a Comment